LiPo Stamp

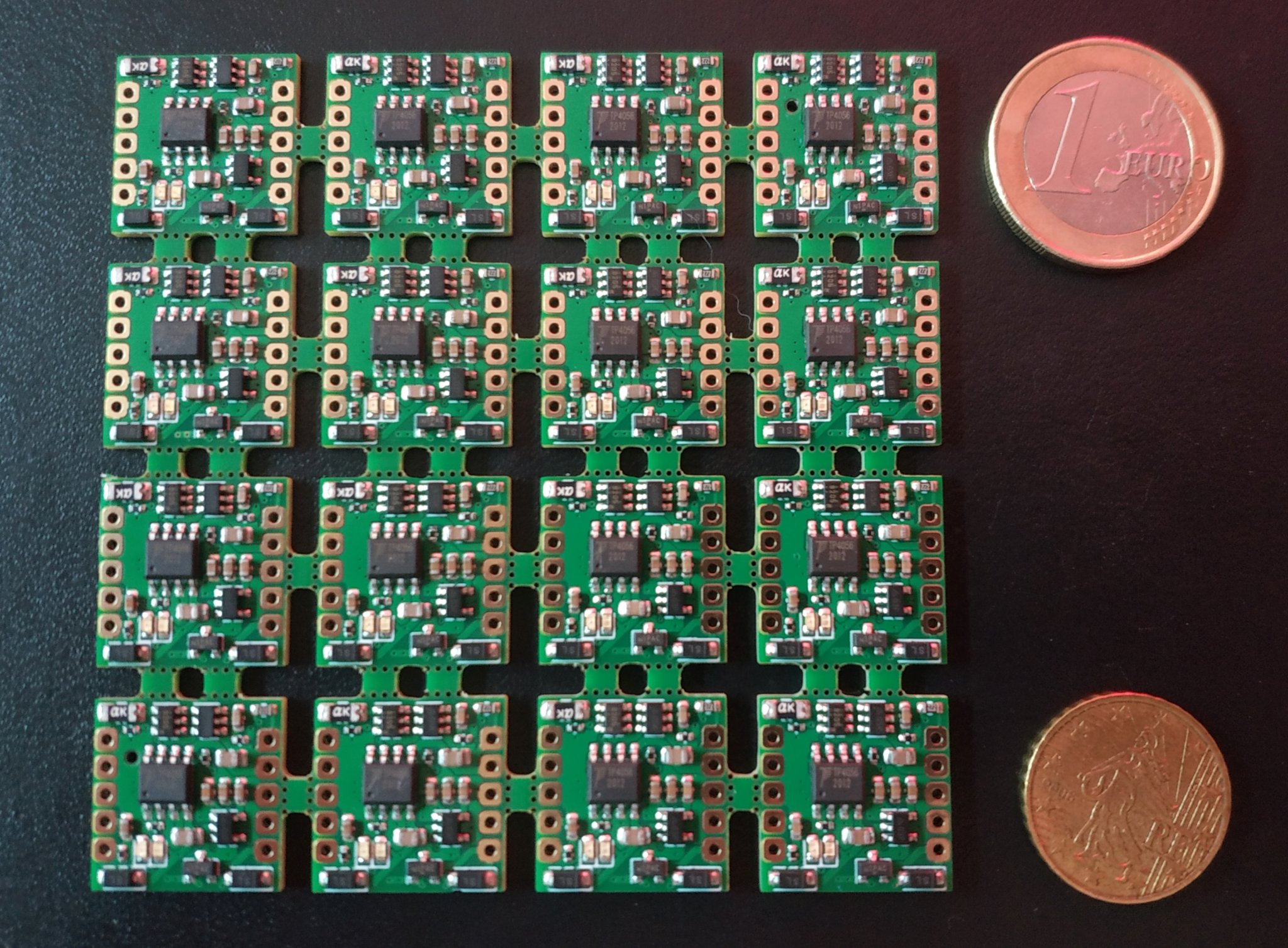

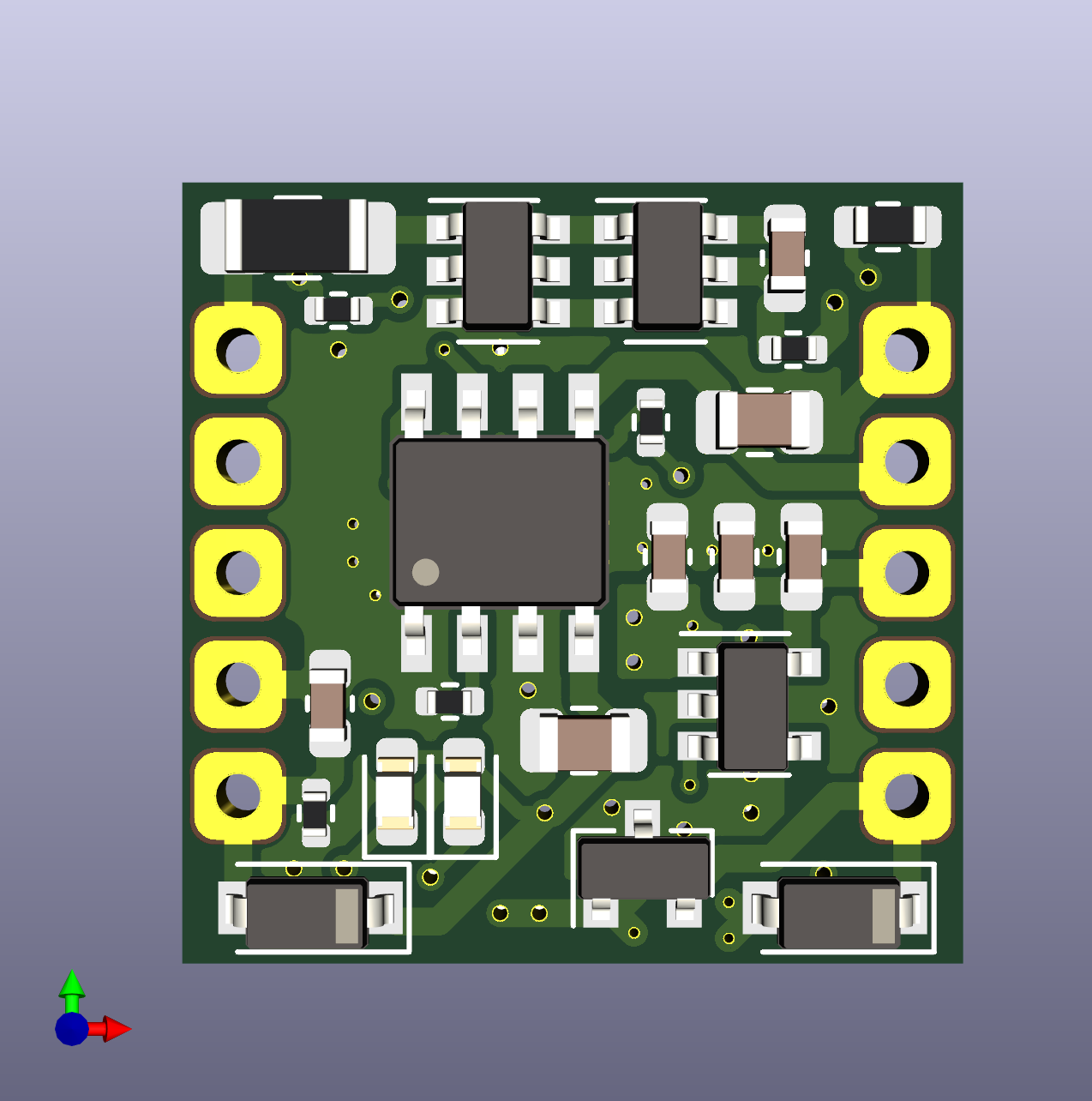

The LiPo Stamp is a small sized, general purpose LiPo charge controller with power path and a 3v3 regulator. Currently the targeted size is 0.7" by 0.7", or just under 18mm square. It is intended to be used with single cell 18650, 21700, pack, or similar batteries.

I intend to use this in projects such as Kuma's Collar.

Features

- TP4056 Charge Controller

- 500mA charging current

- Low voltage trickle charging

- Over/Under-voltage Protection

- AP9101CK6 + FS8205

- Disables battery on over/under charge

- Power Path

- Provides power via USB when connected

- 500mA max output (USB or Battery)

- Switchable 3v3 Regulator

- Default off

- 100mA+ output

- Resettable Polyfuse

- For high current, direct battery applications (e.g. LEDs)

- Max 2A continuous output

The main project page for the LiPo Stamp is hosted on GitHub.

Testing

Implementation of the automated tester is currently going on in this pull request

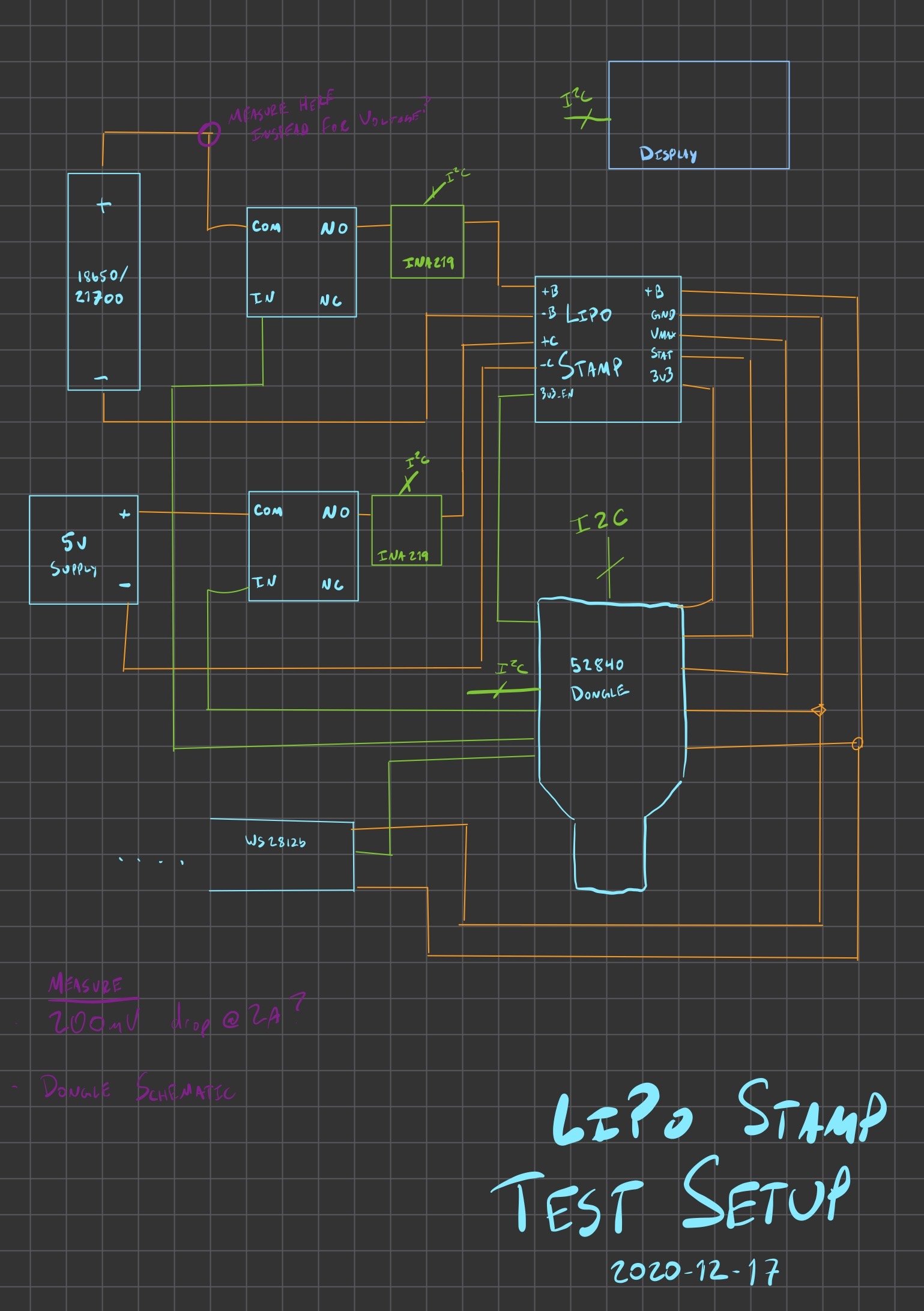

I plan to build a hardware in the loop test rig for the LiPo stamp. It will probably be a proto-version of the KTA, though probably not strictly at the start.

Unsorted test brainstorming

I think I will need the following equipment/setup items for the test cases.

- A LiPo Stamp

- Mounted to a breakout board for easy wiring

- Maybe with headers or screw terminals

- A KTA

- This will "Run" the test

- Also use some ADCs to measure voltage

- Also look control GPIO input/outputs for LiPo stamp

- A 5v supply

- This only needs to provide 500mA for charging, so USB might be suitable if it can power everything

- Otherwise use an external AC/DC supply

- INA219 breakouts

- Measure battery input/output

- Measure 5v charging line

- Relays to connect/disconnect:

- 5v charging source

- Battery connection (high side)

- LED connection (high side)

- WS2812B strip/panel for programmable load

- Some kind of display for monitoring output?

- Protected 18650 cell

- Probably NCR-18650B, rated to 5A discharge, 2.5v cutout

- 3.6v nominal

- PDF Datasheet

- Unprotected 18650/21700 cell

- I might need some kind of custom holder for protected battery cells (if they don't fit the holders I have)

I think I will need at least the following test cases for the board:

- No battery, 5v present

- Check vmax output

- Check 3v3 output (disabled)

- Check 3v3 output (enabled)

- Protected cell

- 5v connected

- Check vmax output

- Check 3v3 output (disabled)

- Check 3v3 output (enabled)

- Verify charging

- Wait for charge complete

- Verify charging complete (no charging)

- Verify LEDs (manual)

- 5v disconnected

- Check vmax output

- Check 3v3 output (disabled)

- Check 3v3 output (enabled)

- Begin discharge pattern

- Verify cutout at low voltage

- Verify LEDs (manual)

- 5v connected

- Polyfuse test

- Charge all the way

- Discharge at steps

- 500mA

- 1000mA

- 1500mA

- 1900mA

- Verify discharge okay, no cutout

- Push discharge above levels

- 2000mA

- 2100mA

- Ensure cutout occurs after XX seconds

- Disconnect load

- Ensure board restores after YY seconds

- Unprotected Cell

- Probably repeat steps above to verify cutout happens because of LiPo Stamp protections, not protected battery

- How to generate load at voltages below the cut-out voltage? We probably need to go as low as 2.5v to verify cut-out.

Test board pinout

- I2C for the INA boards and Display?

- SCL

- PORTB-06

- SDA

- PORTB-07

- SCL

- Analog Inputs

- Battery+ (might be available on INA219?)

- ???

- 5v Source

- Also VBUS for the test system?

- Maybe not? Going through a regulator?

- ???

- Also VBUS for the test system?

- 3v3 Reg Output

- ???

- VMax Output (May be greater than 5v!)

- Voltage Divider?

- ???

- Battery+ (might be available on INA219?)

- Digital Outputs

- 3v3-EN

- ???

- RELAY: 5v Input NO

- ???

- RELAY: Battery Input NO

- ???

- RELAY: WS2812 Panel Connection NO

- ???

- 3v3-EN

- SPI output

- WS2812b Panel

- PORTB-08

- WS2812b Panel